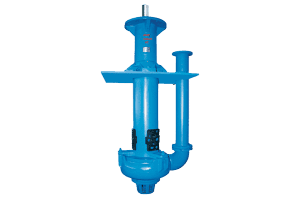

WX(R) / WXA(R) – Series Heavy Duty Slurry Pump

WX(R) / WXA(R) – Heavy Duty Slurry Pump

WX(R) & WXA(R) hard metal/rubber heavy duty slurry pumps are designed for the most difficult pumping applications for highly abrasive , high density or corrosive slurries. Extra thick sections at the critical wear points and superior Impeller structure ensures improved performance with extended wear and minimised maintenance, thus improving cost of ownership.

Rubber lined pumps expand applications to chemical products handling, several different rubber options are available to meet different application requirements.Best fitted in aggressive applications, like mill discharge and tailing transfer

WXA( R ) pumps are improved version of WX(R) pumps, in that it has an adjustable wear plate seated in at the Throatbush. This can be adjusted while the pump is running.

CLEAR WATER PERFORMANCE:

TYPICAL APPLICATIONS:

Usage of versatile wear-resistant and corrosion-resistant materials allows WX(R)/ WXA( R ) series slurry pumps to service in various industries, such as mining mill discharge, delivery of tailings, ash removal in power plant, FGD and coal washing in coal plant, etc.,resulting in low operating cost, as well as minimized maintenance and down time.

WX (A)Pump Quick Selection Chart:

WX(A)R Pump Quick Selection Chart:

Pump Features

Single stage, single suction, overhang shaft, centrifugal, double casing horizontal pump

Material:

Casing are made of ductile Iron, ribs help casing to withstand higher pressures.

Wet Ends - Impellers, liners, volutes are made of high-chrome alloy or rubber or polyurethane, to resist wear, corrosion or impact, parts made of metal or rubber are interchangeable.

Shaft sleeve: Ceramic, tungsten carbide or other hard material are optional for coating, to increase wear resistance.

Bearing Assembly- Grease Lubrication and oil lubrication are optional depend on the usage.

Seal options- -Gland Seal, expeller( centrifugal or dynamic) seal and mechanical seal are optional to fit different application Parts design:

Impeller-Multiple impeller types for diverse applications to get best performance: High efficiency, High efficiency with lower NPSHr, large particle, enhanced performance, flow reducer, Recessed eyes are available.

Liners- different types to match different impellers.